Welcome to the SDCT Tech Website

Small Diameter Copper Tube Heat Exchanger Technology

The industry has spoken! For the vast majority of AC, Refrigeration and Heat Pumping applications, small diameter copper tube (SDCT) is preferred over microchannel aluminum. SDCT technology is critical to the advancement of cooling (AC), refrigeration (R) and heat pumping (HP) systems based on the vapor compression cycle (VCC).

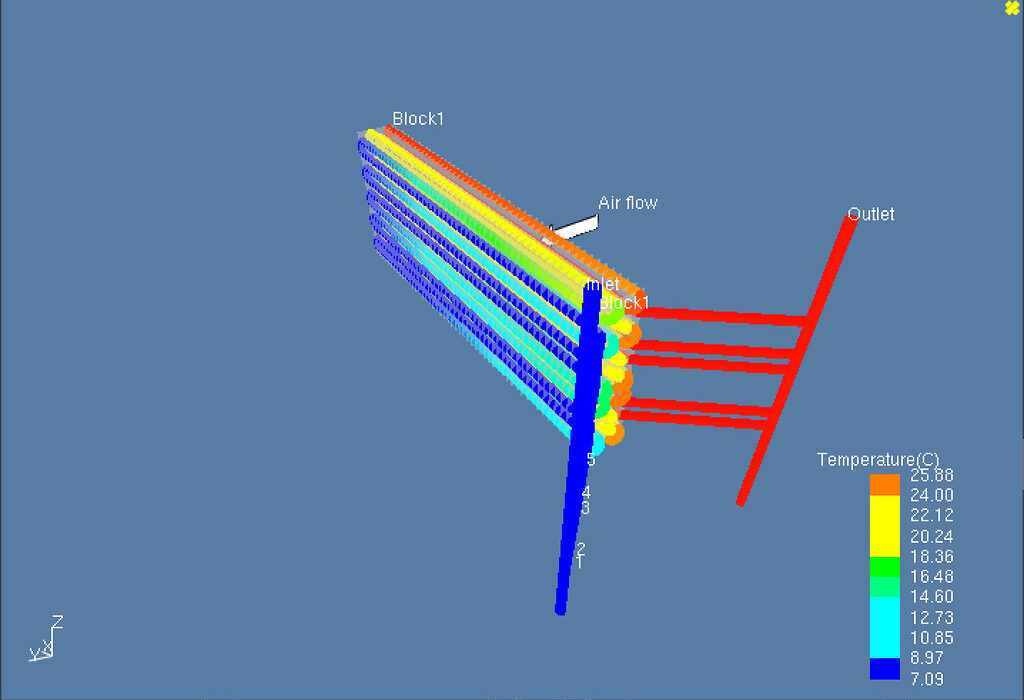

All VCC systems are fundamentally heat pumping systems consisting of a suitable refrigerant, a compressor, an expansion valve, and two heat exchangers: A condenser coil (or gas cooler) downstream from the compressor rejects thermal energy, while an evaporator downstream from the expansion valve absorbs thermal energy.

The purpose of all VCC systems is to efficiently transfer thermal energy from the evaporator coil to the condenser coil. In short, energy is picked up at the evaporator and deposited at the condenser. That is the basis for countless heating, cooling and refrigeration applications, collectively known as AC, Refrigeration and Heat Pumping (ACRHP) applications.

The Tipping Point

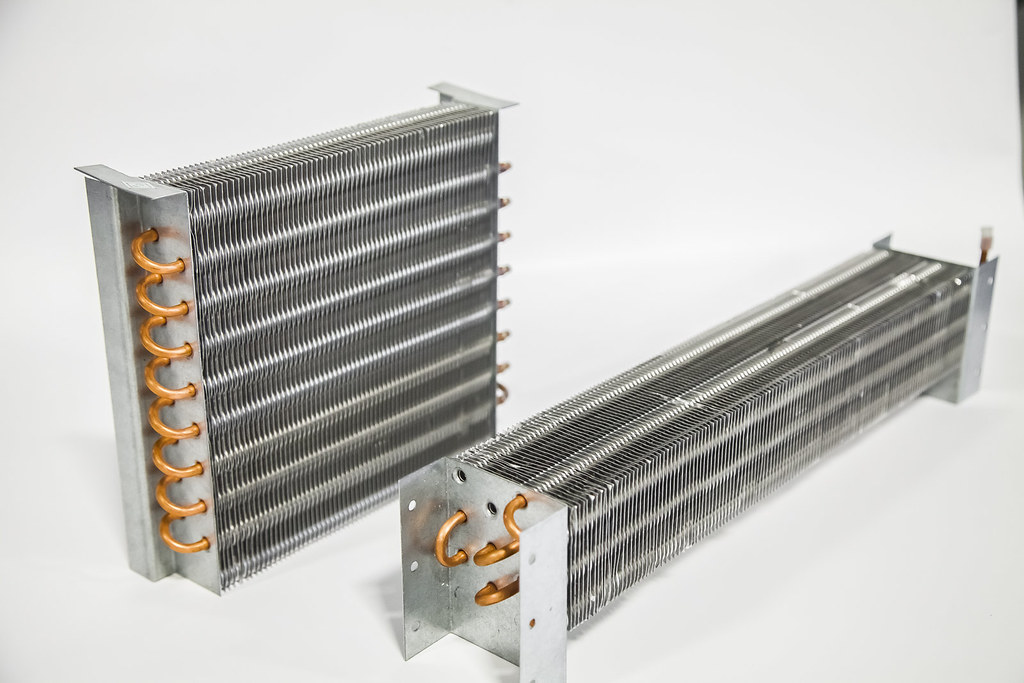

Round Tube Plate Fin (RTPF) coils have been the industry standard for decades. However, beginning around the turn of the millennium, ribbon shaped brazed aluminum microchannel (BAM) tubes with serpentine fins were proposed as substitutes for RTPF coils. BAM heat exchangers had seen success as radiators in the automotive industry.

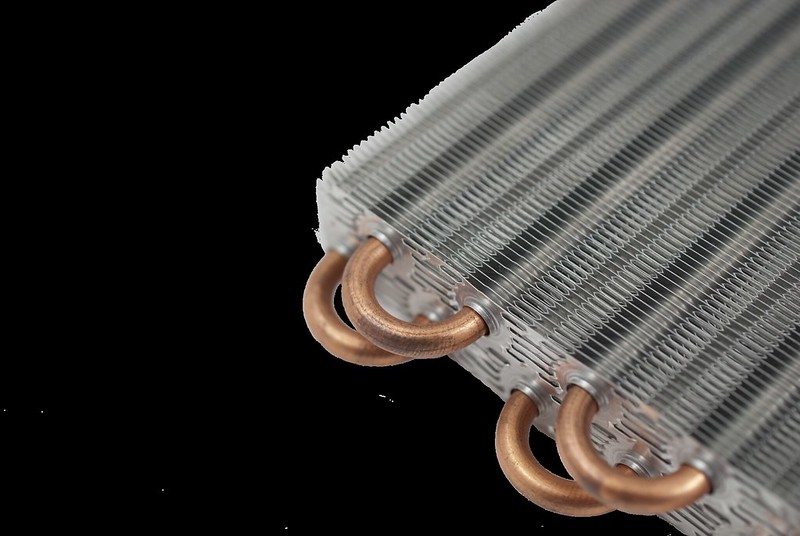

The copper industry responded with the development of smaller diameter copper tubes for AC applications. By 2010, SDCT were appearing in mass produced residential air conditioners, including window-type ACs, Central ACs, and packaged terminal ACs.

Copper tubes with 5 mm outer diameters were used to make highly efficient RTPF coils. What is more, the inner-surfaces of these tubes were enhanced with “microfins,” further improving the inside-the-tube heat transfer coefficients of the tubes.

The new technology was soon recognized as economical and ecofriendly compared to alternatives. The primary benefits of SDCT technology are high energy efficiency, less tube material, reduced size, less refrigerant and corrosion resistance.

The International Copper Association promoted this technology under the “microgroove” service mark for more than a decade and heralded advances through technical papers.

ICA also promoted the technology at industry expos and through advertisements and articles in industry trade magazines as well as the MicroGroove Update newsletter, which was published regularly from 2010 through 2024.

Fast forward to 2025 and SDCTs represent the dominant heat exchanger technology for ACRHP applications globally. Since SDCT technology will play a vital role in achieving sustainability goals for decades to come, ICA will continue to facilitate the sharing of information through this streamlined SDCT Tech website and the SDCT Tech enewsletter.